Experiencing Common Problems With Heavy Equipment? Check Oil Coolers

If your company depends on heavy equipment, then you already know how important oil coolers are to keep your hydraulics and engines running. And if your heavy equipment oil coolers fail, you might not realize anything is amiss until you experience a serious malfunction. When that happens, work can grind to a halt altogether. Operating heavy equipment without a functioning cooling system puts your machines at risk. Ignore the problem, and you could end up triggering catastrophic failures.

That's why it's crucial to maintain and replace heavy equipment oil coolers as quickly as possible. Fortunately, because these heavy equipment components are so vital, your local heavy equipment parts company likely has a number of replacement parts on hand.

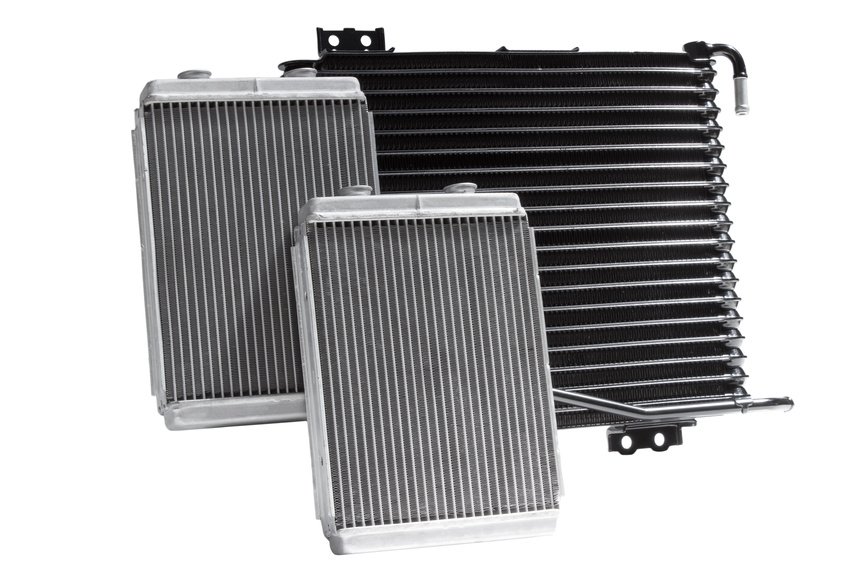

For instance, our Long Island heavy equipment and used Caterpillar parts company has about 65 different oil coolers and related parts at any given time. Of course, not all cooling systems are created equally. So it's crucial to know exactly what you need -- hydraulic oil coolers, transmission oil coolers, radiator coolers, or torque converter oil coolers. But if you're having engine troubles, don't take the "wait and see" approach...

Four Ways Replacement Heavy Equipment Oil Coolers Save You Money

Worldwide, the global construction equipment market is valued at $145.5 billion this year, and North America is the second biggest piece of that market ($25.8 billion). And when it comes to machinery, Caterpillar is king of the hill, generating as much as $65.8 billion a year. Anyone who knows their way around this equipment already knows that without an efficient cooling system, engine and hydraulic oil will get overheated, causing serious damage.

1. By maintaining oil coolers properly, you reduce service and repair costs while also reducing the time and opportunity costs that come from extended machine shutdowns.

2. Too much heat degrades hydraulic oil, rubber, seals, and coats component surfaces with damaging varnish. By keeping optimal temperature, you ensure your hydraulic oil and heavy equipment components last as long as they were designed to.

3. Even if your machines manage to limp along, excess heat will make them inefficient at best, vastly hurting your productivity.

4. Oil can only maintain the correct viscosity at the right temperatures. Once you get outside that ideal range, you risk causing permanent damage from leaks, failed lubrication, and engine failure. Not only is that a waste of good money, it's dangerous.

We could tell you that oil coolers are the most important components in your equipment, but the truth is these machines only work if all their moving parts and fuel function just right.

So here's a pro tip: if you're experiencing problems like the ones described above, schedule heavy equipment servicing ASAP to check out your oil coolers. But also take the time to check out other vital equipment. We know that almost 75% of fluid power failures are a result of contamination from faulty hydraulic filters. Reduce machine downtime even further by taking the time to inspect multiple systems at once. And don't forget to order replacements before it's too late!