Why Hardox Plates Are So Versatile

Heavy equipment parts need to be able to handle a variety of high-pressure situations. From rough terrain to heavy loads, as well as working in harmony with other equipment components, construction equipment needs to be tougher than nails -- literally.

Though the construction industry is one of the most well-established in the world, there are still a number of improvements being made worldwide regarding the integrity of heavy equipment components. While Caterpillar is one of the most recognizable equipment brands, with a global revenue of 65.88 billion in 2012, there are a number of other companies making waves and producing some of the best quality equipment on the market today.

Hardox plates are some of the most revolutionary innovations in construction to date. Developed by SSAB in Sweden and launched in 1974, Hardox is the first modern designed wear plate, meaning that it has strong anti-wear properties. Its unique qualities have skyrocketed it to the top of the line and have proven to be the most effective steel plates on the market. SSAB's ability to continue innovating and growing the Hardox brand has helped the company keep an edge over other steel competitors, the same way that Caterpillar has kept an edge on other construction vehicle companies.

Though primarily used for excavator buckets and dump truck bodies, Hardox plates can be used for load bearing parts as well. In fact, Hardox is suitable for just about any application because of its ability to be molded easily.

Hardox Grades

There are several different grades of Hardox: 400, 450, 500, 550, and 600. Each grade is specifically designed to last through an extended lifetime and is also formable, drillable, and weldable.

The most common grade of Hardox you'll find is 450, which is designed for year-round use. It is primarily used in dumpster bodies and feeders that may carry abrasive materials. Stone quarry excavating machinery is also a suitable candidate for Hardox plating.

Versatility and Strength

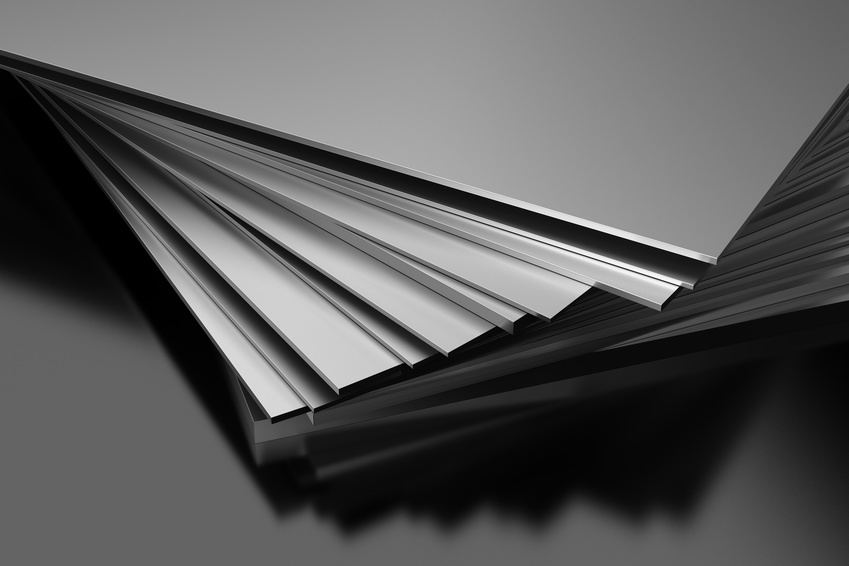

Hardox plates are specifically designed to handle the toughest applications. No amount of wear, tear, and abuse is a match for Hardox steel plating.

With a number of widths and thicknesses available, there is a piece of Hardox steel for everyone.

The beauty of this material is that even after the remaining construction vehicle is no longer in use, the Hardox plating can be reused. LI Heavy Equipment has a premium supply of construction equipment and parts. While our inventory fluctuates frequently, we do carry Hardox steel plates on occasion. Call ahead, though, because they can go quickly.